Uptick in irrigation tracks record rural land prices, bringing previously marginal land into the profit picture

With farmers and rural landowners now facing an El Nino drier climate cycle, more pastoral and livestock properties are enhancing their value and productive capacity with rugged, reliable and low-maintenance irrigation systems.

We are finding a definite uptick in inquiries and installations. Some are for prime properties, which is understandable, but another underlying trend is for irrigation being explored for properties that might have been overlooked in the past as marginal or too remote,” says Matt Eland, from the leading specialist provider of Australian water irrigation systems, Water Dynamics.

A driver of the trend is the increase in farmland values over recent years, he says, citing a Rural Bank Australian Farmland Values Report. Records have been continuously broken in recent years states the Report, with annual growth of up to 30 per cent in some states and a median price of $7087 a hectare. According to the 2023 ABARES (Australian Bureau of Agricultural and Resource Economics and Sciences) report, farmland in Australia has experienced strong growth, accelerating in recent years. Broadacre farmland, for example, has increased by over 195 per cent over 10 years from an average of $1592 to $4689 per hectare.

Naturally, prices are accelerating in areas and states blessed with higher rainfall, but both averages and median prices are pointing in the same direction – up, then up again. Everywhere, good land managers recognise that the value of farmland holds a pivotal role in financial portfolios and overall wellbeing of Australian famers,” says Eland, who is based in Water Dynamics Mt Gambier operation – part of the network of six strategically located branches across Australia.

He was recently involved in an optimisation project at Robin Steen’s Bronzehaven Estate property which increased its productivity and value. The property is located near Naracoorte in South Australia about 100 kilometres north of Mount Gambier and is reliant on groundwater from the Dilwyn Formation.

Sweet Spot

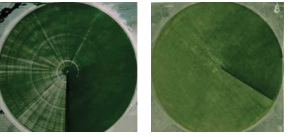

At Bronzehaven Estate, Water Dynamics installed a low-maintenance, high efficiency seven-span 388 metre T-L hydraulic pivot irrigator to increase options for both stocking and cropping capacity. The Estate is in an area remote from utility services, where reliability and low maintenance were essential parameters in the specification mix.

The owner set up the system to grow lucerne for cropping and animal feed initially, while bringing 52 hectares of land into productive use for stock and pastoral use as required.

The size and configuration selected for this project hit a sweet spot in size for centre-pivot irrigation in Australia. Southeastern Australia’s ideal centre pivot size is typically less than used in the US, where 400 metres is standard for paddock areas in most areas of Nebraska, the home of centre pivot manufacturing. That is where T-L is headquartered and from where it has achieved its global success.

But here in Australia, particularly dealing with conditions in remote and previously marginal areas, we like to engineer installations to take account of limited water availability and variety of terrain, so we can deliver the best balance of cover and reliability for maximum efficiency and ongoing productivity gain,” says Matt Eland.

The T-L installation is supported by an inline shaft turbine water pump. In consultation with the client, it was selected from the broad range that Water Dynamics has continuously improved for more than 30 years. The rugged and efficient TL centre pivot system is one of the latest custom installations. More than 2000 of these reliable systems have been installed in areas from Tasmania to the Northern Territory. This is in addition to more than 30,000 installed in Nebraska, where land values are following the same, or steeper, trajectory as Australia.

No two system configurations are truly identical in Australia, because of the need to engineer to suit the conditions in different states and territories, for cropping, pastoral, horticulture and turf. They all have different input, water supply and fertiliser spread rates. Even in South Australia, conditions can differ widely just 50 or 100 km apart.

But there are some common strengths in the technologies we are installing in different properties such as those of Robin Steen’s Estate. These properties are geared for maximum productivity and low maintenance, since areas like Bronzehaven may be remote from infrastructure and services,” says Matt Eland.

The features of this installation that are key to its durability, versatility and reliability include:

- T-L hydrostatic fixed planetary drive system. T-L planetary gear systems are the only planetary system available in Australia that have proven their reliability locally and internationally. They are totally enclosed and directly coupled to the drive, eliminating the centre-drive gearbox and conventional U-joints. “The drives are also easily accessible if service is ever required, which is a major asset on more remote properties,” says Matt Eland. The hydrostatically powered T-L systems are designed to deliver continuous movement. Gearbox wear is drastically reduced due to the absence of an electrically driven system stop-start operation. T-L systems deliver the most consistent water pattern available ensuring that water and chemicals are evenly distributed over the crop.

- Automated GPS control. The latest T-L Precision Point Control III mid-level pivot management system extends both reliability and precision benefits for properties such as Bronzehaven, while reducing manned inputs. With the addition of a GPS Antenna at the end tower or a Rotary Encoder at the pivot point, the PPC III Control Panel can automate the operation of several functions. When combined with PPC III, T-L’s hydrostatic design and continuous system movement assures uniform water application, improved crop production, and effective system management.

- T-L planetary drive units receive continuous power to each wheel from hydraulic motors directly coupled to the final drive gear assembly. They are specifically designed for low-speed, high-torque applications, operating at nearly 90 per cent drive efficiency to get the power to the ground with a minimum of wasted energy. Bronzehaven’s tubeless 14.9 x 24-inch purpose-manufactured irrigation tyres are installed on galvanised wheel rims.

- AgSense Precision Link Web-Based Pivot Management. Developed by AgSense, LLC and T-L, and applied globally, Precision Link, coupled with the Precision Point III allows full remote pivot control and monitoring capabilities, including managing the pivot from a computer or mobile device through a simple web interface. This enables users to achieve labour and fuel savings by logging on to the AgSense WagNet website to monitor and control the pivot, without having to travel to the field site.

- Vertiline diesel turbine pump units. These are particularly suited to more remote applications where utility services are not readily available. They are based on familiar diesel technology and are ideal for sites where electric power is not available or costly to access. The diesel pumps also eliminate electrical hazards for DIY landholders seeking to maintain production without the time and expense of service callouts.

- Senniger LDN (Low Drift Nozzle) bubble sprinklers. These are deployed at 1m spacing at Bronzehaven, at low 6psi pressure thereby reducing pumping costs. The use of this versatile technology also means a single type of applicator can be used for multiple Low Energy Precision Applications (LEPA), spray irrigation and chemigation. “The technology options give different types of land users precise control of their sprinklers’ droplet size, trajectory and application pattern. This makes the LDN capable of adapting to various crop, environmental and soil requirements,” says Matt Eland.

No one-size-fits-all

The Bronzehaven system’s hydraulic pumping unit is driven from the irrigation engine for engineering simplicity and efficiency. The main unit, with a 6000l diesel tank, is housed in a custom-fabricated Zincalume structure with a concrete pad.

Stainless steel components are extensively used in critical applications such as tower oil lines and alignment cables. These complement the long runs of galvanised piping with internal poly lining for low maintenance.

“Properly designed systems can’t be formula-built,” says Matt Eland. There is no magic formula, no one-size-fits-all. Every farm or landholding is different.

But there are, of course, common design components that are strongly suited to multiple applications, innovations that are proven in service. This is the case with many installations where customers come back again and again.

The best way to ensure irrigation success is to:

- Work with a company that stocks a solid range of technologies (such as T-L), has achieved sustained success over time, and invests in durability, reliability and continuous innovation in its product ranges.

- Find a company based in your area and knows the subtle differences that separate outstanding success from troublesome failure and takes pride in the local expertise it has developed after investing in projects over time.

- Deal with a stable, long-term company with the people and the products to provide you optimised performance and reliability first up, but will also be there to service, adapt and respond to the rapidly changing needs of cropping, livestock, dairy, horticulture, viticulture, turf and land industries.

- Talk to customers and to service providers in detail. Determine the extent of their knowledge, and check if they are just reading from a script. Farming and property management is a place for real knowledge, because any good farmer or landowner knows that optimising land value, crop value and stock value is a value equation over time.

Farming is not a five-minute business. Good decisions take time, research, deliberation and dealing with people you trust. There is no value in something that is just the cheapest on the market or not backed by service in the field. Or built for today, but not engineered to respond flexibly to a rapidly changing tomorrow in which efficient use of water and land is not an option, but an imperative,” says Matt Eland.

About Water Dynamics

Our local Water Dynamics team here in Mr Gambier – and major branches in Yarrawonga, Vic, Mildura VIC, Darwin, NT · Longford, TAS and Mt Gambier, SA includes a blend of product experts, irrigation designers and installers. Our staff are very well known in the industry and some have previously owned and operated their own landscaping and irrigation businesses.

We pride ourselves on good old-fashioned customer service so you know you’ll get the personal attention you’re looking for when you work with us on a project, or come into store. Our unique regional focus means we understand local conditions and challenges, and have the relevant skills to provide the right products and technical advice to keep irrigation systems operating at peak efficiency all year round, now and in the future.

For product and sales information, please contact Matt Eland

Water Dynamics

P +61 8 7723 2600 | F | M 0417699735

E [email protected]

233 Jubilee Hwy West, Mt Gambier, SA 5290

Latest Projects

Water Dynamics partnerships welcome a greener and stylishly sustainable historic main entrance to Darwin

The Stuart Highway entrance to Darwin is the dynamic northern terminus of this 2,720 km highway that is one of…

Read More...

Early adopter of citrus growing automation achieves cost-efficiency, connectivity, and conservation in the one package

An Australian citrus grower at the forefront of automation efficiencies sweeping through the industry is increasing production quality and…

Read More...