Valves for Irrigation

Irrigation valves control and direct water flow in your system. Correct selection, design and installation are critical — valves are mostly maintenance-free but fail when chosen or installed incorrectly. Get it right the first time.

Our valve range

Water Dynamics stocks a wide selection of valves, valve boxes and water meter boxes for domestic, commercial and agricultural irrigation systems. Choose from brass, stainless steel, PVC, poly, cast iron and nylon materials.

- Solenoid valves

- Control valves

- Valve boxes & water meter boxes

- Backflow prevention valves (backflow devices)

- Butterfly valves

- Pressure reducing valves

- Wafer check valves

- Air / vacuum release valves

- Float valves

- Foot valves

- Check valves (non-return / foot valves)

- Gate valves

- Ball valves

- Materials & brands

Detailed Guide — How to choose & use each irrigation valve (Australia)

Control valves

What they do: Automatically regulate water flow and pressure within an irrigation system, ensuring consistent delivery to crops or turf. They can open, close, throttle, or maintain pressure depending on system design.

Typical uses:

- Mainline and zone regulation in agriculture, turf, and landscape irrigation

- Pump and filter stations for pressure control

- Automated systems integrated with controllers and solenoids

Key features:

- Pilot-operated or direct-acting designs available

- Can perform multiple functions: pressure reducing, pressure sustaining, flow control, level control

- Compatible with automation (electric, hydraulic or pneumatic actuation)

Materials: ductile iron, stainless steel, or reinforced polymers for durability in demanding environments

Install tips:

- Always size based on flow/pressure curves, not just pipe diameter

- Install isolation valves on either side for servicing

- Use filtration upstream to protect pilots and diaphragms from debris

Ensure correct orientation and adequate clearance for pilot tubing and maintenance access

Solenoid valves

What they do: Electrically actuated zone control valves for irrigation controllers.

- Voltage compatibility (24VAC typical), flow rating, IP/wiring protection.

- Diaphragm (pilot-operated) for higher flows; direct-acting for low flows/low pressure.

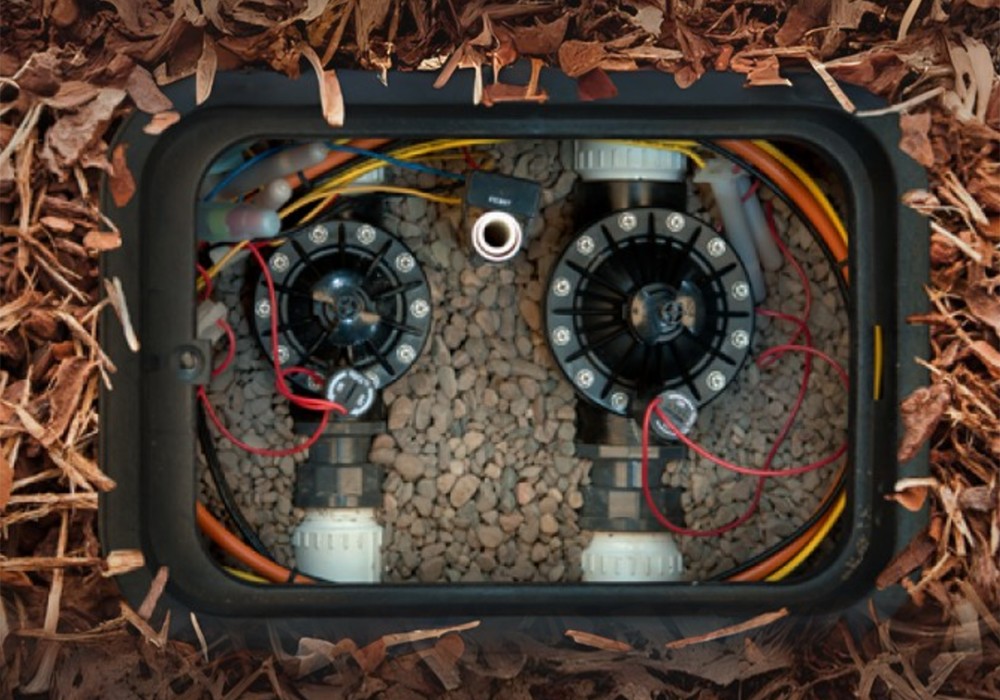

Valve boxes & water meter boxes

What they do: Protect and give access to valves, manifolds, solenoids and meters.

- Choose heavy-duty/lockable for public/commercial areas.

- Size for present and future manifold footprint + wiring space.

Backflow prevention valves (backflow devices)

What they do: Stop contaminated water reversing into potable mains.

Typical uses: Town water connections with cross-connection risk (chemicals, tanks, pumps).

- Choose device by risk level: dual-check, RPZ, PVB (per authority rules).

- Comply with Plumbing Code of Australia and local authority testing regimes.

Install & maintenance: Keep accessible for annual testing, correct orientation, required clearances.

Butterfly valves

What they do: Throttle or isolate using a central disc—great for larger diameters.

- Seats: EPDM/NBR/PTFE; pick to match water chemistry.

- Lugged vs wafer; gear/electric actuators sized by torque.

Pressure reducing valves (PRV)

What they do: Regulate downstream pressure despite upstream fluctuation.

- Match model to required set pressure and flow (check curves).

- Direct-acting is common; pilot-operated for larger flows.

Wafer check valves

What they do: Low-profile non-return valve that fits between flanges.

- Pick spring-assist or flapped by required closure speed.

- Confirm flange compatibility and inspect for debris periodically.

Air / vacuum release valves

What they do: Allow trapped air to escape from a pressurised pipeline and prevent vacuum formation.

Typical uses: Mainlines, long lateral runs, end of lines, high points and pumps.

- Use combination air valves at pump start/stop locations and high points.

- Size by line volume and pressure; check model air-release charts.

- Materials: brass, stainless or engineered polymers; EPDM/NBR internals as water quality dictates.

Install tips: Mount at high points, add isolation valve for service, avoid sandy inlets.

Float valves

What they do: Open/close with liquid level; used for tanks & troughs.

- High-flow models for large tanks—check flow curves.

- Robust floats/long arms for variable surfaces.

Foot valves

What they do: Check valve with strainer on pump suction to maintain prime and block debris.

- Balance strainer mesh for debris exclusion vs adequate flow.

- Materials resilient to local water chemistry.

Check valves (non-return)

What they do:The Model 70N-EN Check Valve is a non-slam, lift type, non-return valve that opens to allow flow in the required direction and smoothly closes drip tight to prevent backflow.

- Types: spring, wafer, swing—choose for closure speed/space.

- Install with correct flow direction and inlet straight run.

Gate valves

What they do: Full open/close isolation with low pressure drop (not for throttling).

- Use wedge gate valves for reliable sealing.

- Not ideal for frequent cycling—prefer ball/butterfly.

Ball valves

What they do: Quarter-turn isolation with high flow capacity.

Typical uses: Zone isolation, mains shut-off, small/medium lines.

- Full-bore for minimal pressure drop.

- Materials: brass/stainless for durability; poly for corrosive/low-cost applications.

Materials & brands

We stock brass, stainless steel, poly, PVC, cast iron and nylon across leading Australian suppliers to suit different pressures and environments.

Need help choosing?

Visit our store or call 1800 571 812 — our team can help with valve selection, sizing, replacement and compliance advice. For trade and large projects we offer quotes and bulk supply.